Brake Discs

Brake Disc Product Overview

Brake discs – or brake rotors as they are also known – have been a key component of a braking system invented in the late 1800s but still relied on today.

As cars have grown bigger and quicker so brake discs have had to evolve to improve their breaking power.

And over the course of the last three decades, the MAT Foundry Group have played a key role in that evolution. So much so we’re now firmly established as one of the world’s leading manufacturers of this all-important car part.

Five separate facilities, spread across five separate countries and three separate continents, combine to cast, machine and distribute discs fundamental to some of our best loved performance, passenger, commercial and racing vehicles.

Specialists in all things brake discs, we currently machine 15 million of them each and every year – all to an industry leading standard.

How Do Brake Discs Work?

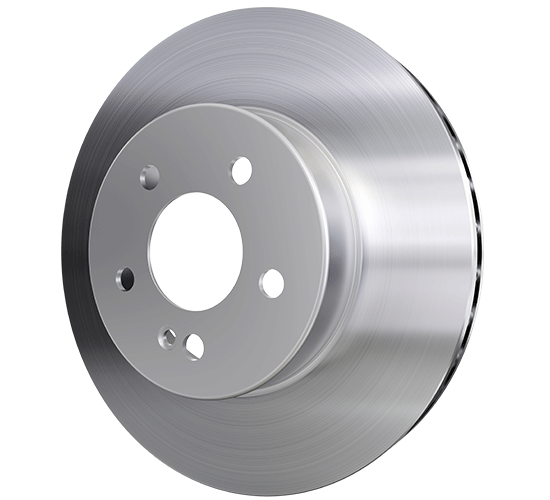

Brake discs are typically formed of iron or carbon composite and are attached to a car’s suspension.

When a driver comes to brake, the disc is gripped by a nearby brake pad, itself held together by a brake calliper.

The resulting friction conspires to slow the vehicle, bringing it to a complete halt if enough pressure is applied.

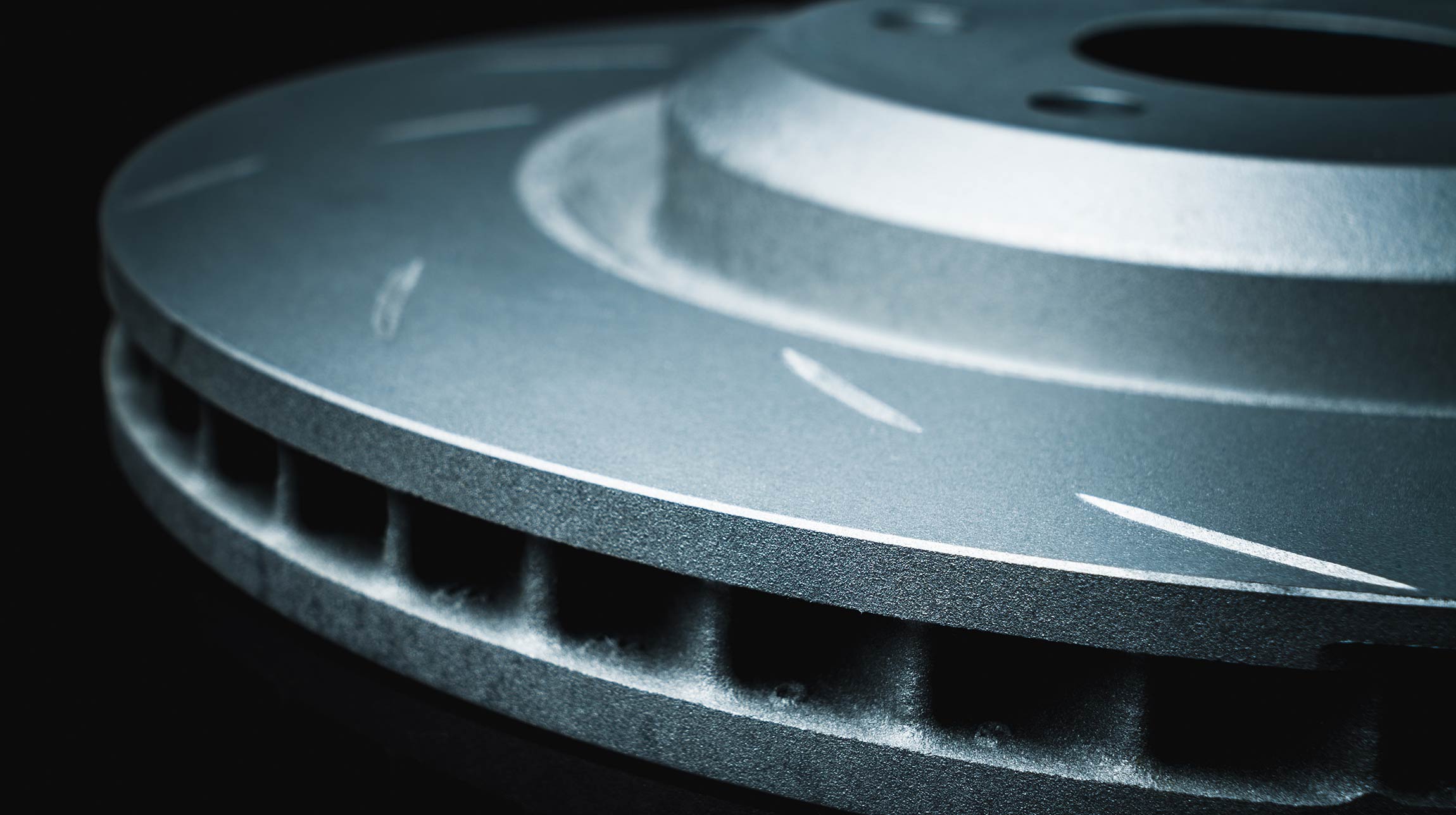

Brake discs, which are fixed to each wheel, must withstand soaring temperatures and to help with this, modern versions are heavily ventilated. Vented designs vary according to the manufacturer and their design specifications. MAT Foundry offer customisation to suppliers.

Brake discs have endured and continue to present a more effective option than the only real alternative, brake drums, which fade all too readily.

Several variations have materialised in recent decades, including Flat, Drilled, Slotted and Dimpled brake discs – all carrying their own benefits.

Whatever the form, most succeed in dissipating heat quickly, providing consistent, reliable braking performance.

Motorbikes and latterly road bikes make use of the same part, one the motoring world cannot do without.

Brake Disc Facts

MAT Foundry machine 15 million brake discs a year

We manufacture brake discs for passenger, commercial and racing vehicles

We work to an average operating temperature of 350°

The minimum thickness of a brake disc is 37mm

Production Facilities

MAT Dalian Auto Parts

Eurac Poole

Eurac Lemgo

Eurac Hradec

Mincer