Raw Materials

Our raw materials include steel scrap, cast iron scrap, cast iron borings, ferro alloys, sand, bentonite and more.

Melting Furnace

Our melting furnaces allow for greater efficiency, reducing melting time, increasing control of power and cutting pollution.

Locality

All of our production facilities strive to source materials from the surrounding area.

Sand Reclamation

Our Eurac Poole plant has invested in secondary attribution unit, reducing the consumption of new sand by 5,000 tonnes a year.

Driving Down Scrap

The MAT Foundry Group have partnered with DISA, acquiring their Monitizer | PRESCRIBE tool to reduce scrap across our operation.

3 New Green Projects

We're proud to announce three new sustainability projects across our international operations for 2023.

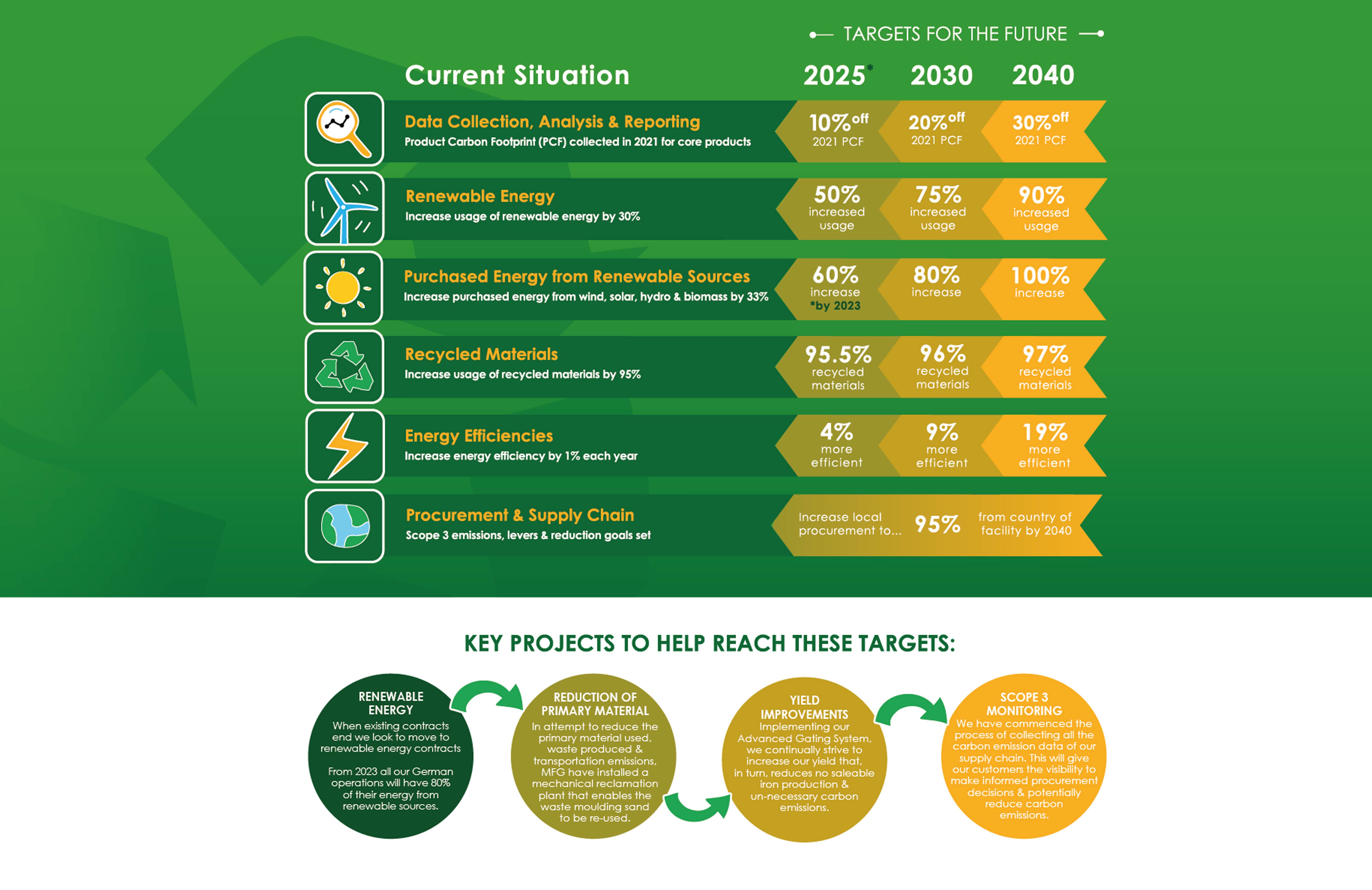

Green Initiatives

Sustainability is important to MAT Foundry. This is why our facilities hold the ISO 14001 environmental accreditation. We're seeing an enormous push from OEMs and Tier 1 suppliers to become carbon neutral by 2040. A growing number are submitting requests for quotations that consider carbon emissions. This has inspired MAT to further reduce our own.

Want to know more about our Sustainability measures?

Did you know?

60% of all MAT Foundry castings are despatched using multi use packaging...

Did you know?

30% of all energy consumed by the MAT Foundry Group is renewable…

Did you know?

90% of all waste generated by the MAT Foundry Group is recycled

Did you know?

Our state-of-the-art medium frequency coreless induction melting is roughly 45% more efficient than cupola

Did you know?

90% of purchased materials and services are from the country in which the facility using them is based