Bloodhound SSC - 1000mph Land Speed Record

Back in 1997, Andy Green driving Thrust SSC shattered the land speed record by the largest margin in the records history when he achieved a top speed of 763mph - becoming the first and only supersonic man on land – and beating the previous record of 634mph set by Richard Noble driving Thrust 2 back in 1983.

RECORDS

Richard Noble was the key figure in both teams and he’s been working on another land speed record attempt since 2007 which is now nearing fruition, having completed runway testing at the end of October 2017. Andy Green remains as driver for the attempt.

Bloodhound SSC, as it’s known, is the latest vehicle produced by the team and they aim to beat the current record by even greater margin than last time. Thrust SSC beat Thrust 2 by 27%, this time they want to do it by 31% - which means Bloodhound SSC will have to exceed 1000mph to achieve this double target. It has been projected to top 1050mph if all goes well.

Achieving this will be the culmination of another decade of work on top of the years spent developing the previous two cars, but this time things are a little different.

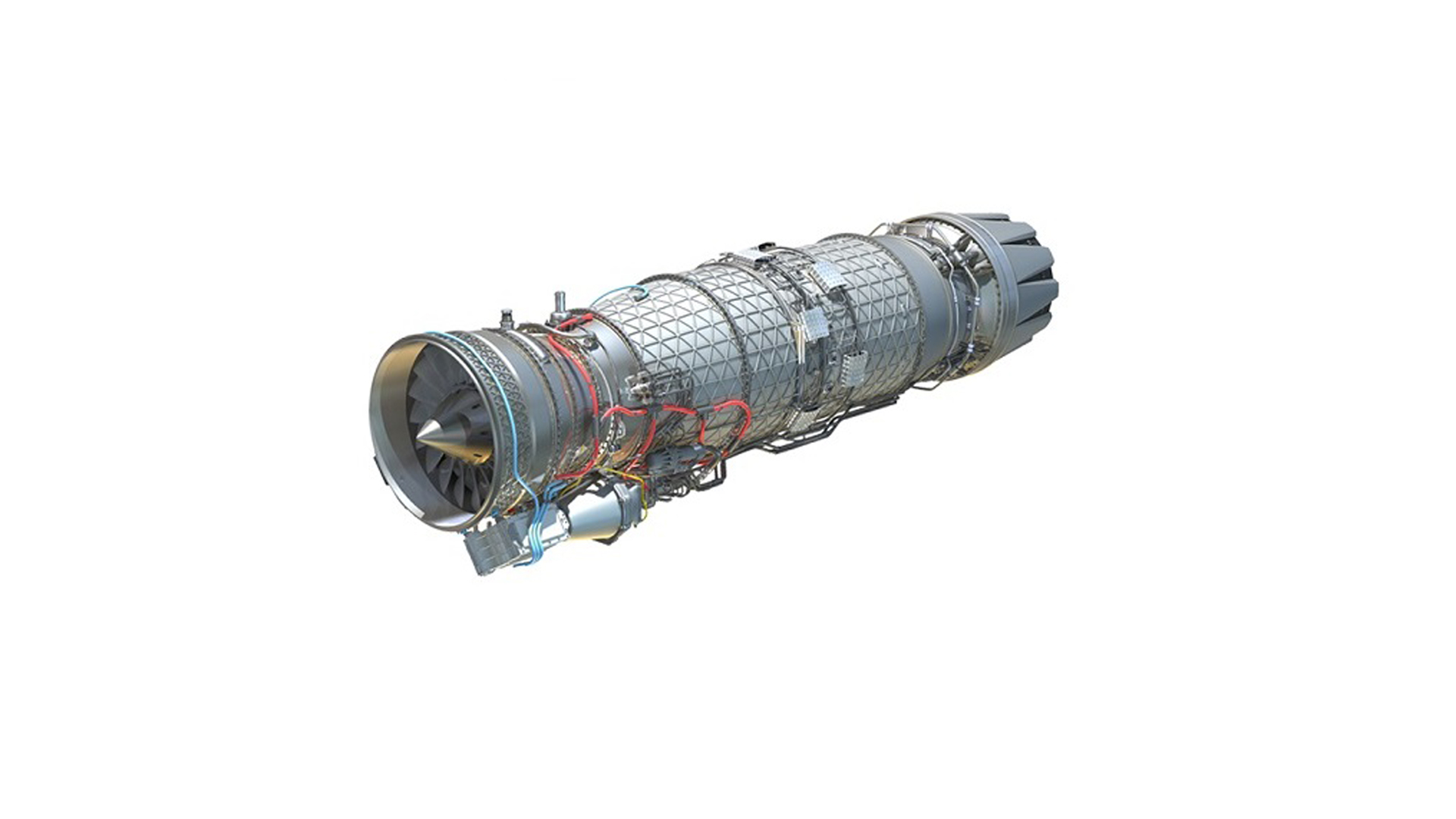

Whereas Thrust SSC achieved its record using a pair of 30 year old engines and salvaged computer systems from military vehicles; Bloodhound SSC is using one of the best engines in the world donated to them by the Royal Air Force – the Rolls Royce EJ200 from a Eurofighter Typhoon jetfighter.

This single engine will push them far beyond Thrust SSC’s potential which used two salvaged F4 Phantom engines. The team actually have three of the EJ200 engines to use and test with, but the car only needs just the one.

This single engine will push them far beyond Thrust SSC’s potential which used two salvaged F4 Phantom engines. The team actually have three of the EJ200 engines to use and test with, but the car only needs just the one.

BOUNDARIES

Achieving 1000mph will be a staggering achievement; the physics involved are mind boggling. The team’s engineering skills will be put to the ultimate test which is really what makes the project so exciting. How do you get a car to survive travelling across the ground at speeds only ever seen by machines flying through the considerably smoother air?

The answer is science and engineering – and lots of it. The precision with which every component has to be built and assembled to withstand the ordeal leaves no margin for error. Any imbalance would have potentially catastrophic consequences, as the tiny vibrations caused by the imbalance at those speeds would destroy other components in seconds.

Because of this the wheels have become a major focus for the project. No tyres could ever hope to withstand the pounding these wheels will take so they are instead made from solid metal. An Aluminium-Zinc alloy has been selected for its outstanding strength to weight ratio, and from it are forged and machined the precision engineered 95kg discs.

Spinning at over 10,000 rpm when at top speed, they are tough enough to withstand the 50,000g the wheel edges will be pulling at this point – so fast they would heat to almost 100C just through air friction alone.

STOPPING DISTANCE

Difficult as it is getting the car up to its target speed of 1000mph, it’s even harder getting it to stop safely. Things like brakes discs tend to disintegrate at even half those speeds – as the team found out when they attempted to use a system from a fighter jet…and it exploded.

To stop the car fully, and accurately - which is crucial for the turnaround time to do the all-important second run and qualify for the record – a five stage process is followed:

- 1000mph – At top speed the throttle is closed off and the car decelerates.

- 800mph – The airbrake is deployed.

- Below 650mph – Parachute deployed.

- Below 400mph – Second parachute deployed if necessary.

- Below 250mph – Wheel brakes applied for final stop at the end of the track.

At almost every stage of this process of slowing the car, the driver will be experiencing 3g of force as it loses 60mph per second (think about that in your own car). The final stage of using the wheel brakes only accounts for 1% of the total braking forces applied to the vehicle during its deceleration and it will take a total distance of four and a half miles to stop the seven and a half tonne car.

REVOLUTION

This latest attempt on the land speed record isn’t merely for the vanity of extending the grip on the title (although it’s still nice); it’s also addressing an issue we have discussed before – the engineering shortage.

Inspiration as motivation has been identified as a key positive factor on the numbers entering into careers in engineering. Post turn of the millennium Thrust SSC was exactly what was needed; following in the footsteps of other great engineering feats like Concorde or the Avro Vulcan it gave youngsters and school leavers something to dream about, that one day they too could help build something so iconic.

But the world has changed again.

There is now more demand for engineering skills than ever before as we enter into what is now being recognised as a technological revolution. Building without regard for the consequences is no longer acceptable, or in our interest as a species.

Technological advancement is now being achieved without damaging the environment by embracing ‘Green’ technology - and this is what is fuelling the demand for skills. Every piece of technology developed since the industrial revolution is being re-examined and reimagined to minimise its impact on the world around us – and there currently isn’t enough skilled people to do it all.

Bloodhound SSC is hoping to do its part when it breaks the 1000mph barrier and inspire the next generation to one day surpass their achievement and do something even greater.