Insights from ChinaBrake 2025: The Future of Braking Technology

Shanghai, China — October 2025

Last month, MAT Foundry Group attended the ChinaBrake 2025 Conference in Shanghai, one of the most influential global forums for the braking industry. The event brought together leading OEMs, Tier 1 suppliers, and innovators to discuss the technologies shaping the next generation of braking systems.

Stewart Wren, represented Mat Foundry Group at the Exhibition and shared his reflections on the conference and what it revealed about the pace of change within the automotive sector.

“It was a fantastic opportunity for me to attend ChinaBrake 2025, meeting with industry experts shaping the future of braking technology. Regulatory hurdles are redefining what’s possible, as brake dust emissions face tighter limits, EVs demand lighter components, and regenerative braking changes the way friction brakes are used.”

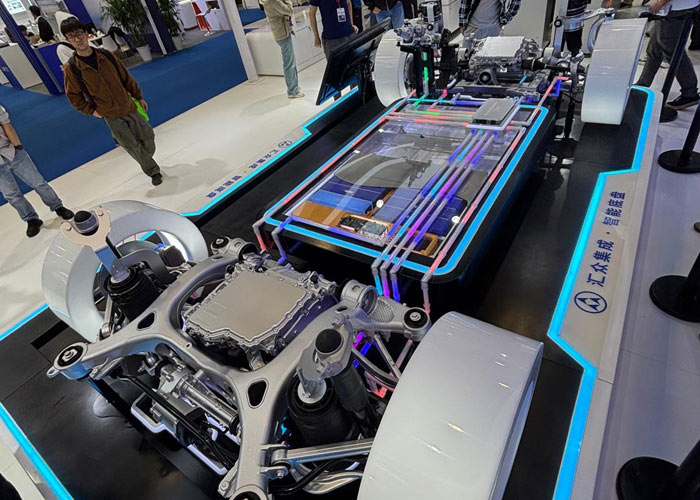

China’s rapid adoption of electric vehicles (EVs) is driving a new era for braking systems. The country’s broadening focus on sustainability, combined with enormous production capacity, is pushing innovation at an unprecedented rate.

One of the most discussed topics at the conference was non-exhaust emissions, particularly brake dust. While the upcoming Euro 7 standards in Europe are set to introduce the first-ever limits on PM10 brake emissions, China appears ready to go further.

The proposed China 7 regulation, expected to take effect in 2026, may introduce even stricter thresholds for particulate emissions.

To meet these targets, Chinese manufacturers are developing advanced solutions such as Laser Clad coatings and low-wear powder formulations, innovations that could set new global benchmarks for clean braking.

Lightweighting Takes Centre Stage

Reducing component mass remains a top priority, particularly for electric and autonomous vehicles. At ChinaBrake, suppliers presented a wide range of carbon-ceramic and aluminium metal-matrix composite (MMC) brake rotors designed to cut weight while maintaining performance and durability.

“Lightweighting was perhaps the foremost concern,” Stewart explained. “The future of mobility is lightweight, autonomous, and long-lasting, and braking systems must evolve to support that vision.”

For MAT Foundry Group, the challenge is clear: to continue advancing material technologies and manufacturing processes that deliver robust, lightweight solutions without compromising safety or reliability.

The Rise of Electro-Mechanical Braking

With the majority of China’s new vehicles now electrified, Electro-Mechanical Brakes (EMBs) and brake-by-wire systems are moving from concept to commercial reality. These technologies remove hydraulic components, reduce maintenance, and integrate more closely with regenerative braking systems.

“Catering to a near-fully electrified market, the conference showcased an impressive array of EMBs and intelligent braking architectures,” Stewart noted.

As this transition accelerates, MAT Foundry Group is aligning its rotor design and material strategy with the demands of next-generation braking systems, ensuring compatibility with EMB platforms and the evolving dynamics of EV braking.

Global Competition and Opportunity

ChinaBrake 2025 highlighted how quickly braking technology is evolving, driven by electrification, sustainability and intelligent vehicle systems. For MAT Foundry Group, these are not distant trends. They are opportunities we are already acting on.

To maintain our market leading position, it is important for us to stay up to date with new technology, emerging trends and new materials. This means considering developments in the wider market as well as reviewing our own production methods. Our goal is to reduce emissions, lower weight and improve performance. By combining decades of foundry expertise with advanced research and development in coatings, hybrid materials and process automation, we ensure our products remain at the forefront of global braking innovation.

What we saw in Shanghai confirms that our strategy is on the right path. A focus on technical excellence, sustainable manufacturing and close collaboration with OEM and Tier 1 partners is the right direction. These strengths position MAT Foundry Group to meet the challenges of tomorrow’s mobility and to play a role in shaping the next generation of braking systems worldwide.