Building A Unified Approach to Quality Across MAT Foundry Group

At MAT Foundry Group we continue to strengthen the sense of unity that binds our global operations. This means working as one team with one approach, whether we are talking about process development, production efficiency or the daily decisions that shape our products. Our talented workforce hold a wealth of knowledge and experience and we are continuously looking at ways to reinforce this alignment and to encourage cross group collaborative working partnerships.

When producing safety critical components there can be no compromise. Our quality procedures must be robust and repeatable across all foundries and machining centres. Customers rely on us to deliver consistency and reliability every time, and that responsibility is something we take seriously. This commitment is one of the reasons our group is trusted by some of the most recognised names in the industry. They rely on us because every site applies the same discipline, delivering the same high standard across the globe.

A key part of protecting this trust is the ongoing effort to review and standardise practices across the business. Whether we are supporting OEMs, Tier 1 suppliers or the aftermarket, our processes must remain clear, measurable and scalable. A unified approach not only strengthens quality outcomes, it also gives long term partners the confidence that MAT Foundry Group delivers the same level of discipline and control across every location.

To support this work our Quality Group Lead, Tim Abbiss, recently visited our teams in Dalian, China and at our newest site, MAT Foundry Mexico. The focus was training on the AIAG and VDA FMEA handbook and scoring criteria. These sessions were used to simulate quality system updates and reinforce alignment with IATF 16949 requirements. They also form part of our wider commitment to employee development, ensuring teams stay informed about current automotive quality tools and techniques.

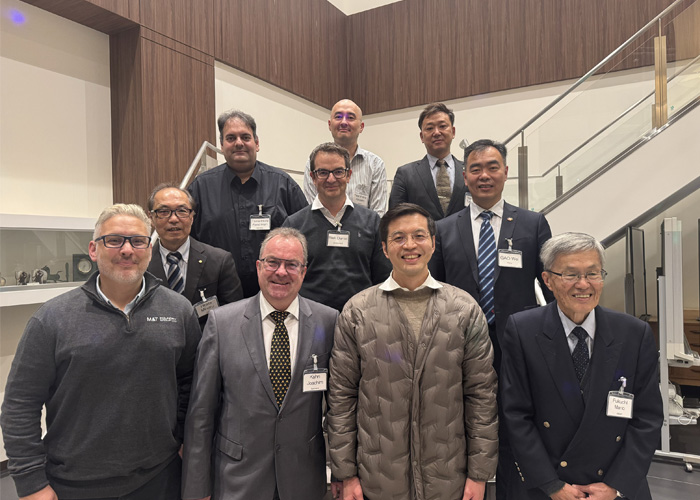

Following his time in China, Tim travelled to Tokyo to represent the British Standards Institution (BSI) at the ISO technical meeting for Foundry Machining. This committee is responsible for developing and refining international standards for the machinery and processes used within the global foundry industry. Discussions centred on safety, sustainability and the evolving needs of modern manufacturing. Tim’s involvement ensures MAT Foundry Group remains closely aligned with emerging international requirements and continues to have a voice in shaping the future direction of the industry.

At the heart of MAT Foundry Group is a drive for continuous improvement, both in how we operate and how the wider industry moves forward. We are strengthening and standardising the way we work across all sites, ensuring consistency and alignment throughout the group. At the same time, we are helping to shape the future of our industry through active participation with the BSI and ISO, bringing our experience and perspective to global discussions on safety, sustainability and the evolving needs of modern manufacturing. This dual focus shows our commitment to progress and our willingness to drive improvement, both within our own operations and across the wider foundry sector. It is this proactive approach that continues to earn the confidence of our customers and partners.