Can You Run An Engine Without Oil?

The presence of oil and its distribution is absolutely crucial to an engines continued operation. Engines can work without oil, but the effect is so damaging they are only capable of running for less than 30 minutes until failing - and in most cases, it’s a lot quicker than that.

WORK HORSES

The amount of potential wear an engine can suffer in an extremely short space of time cannot be overstated. Even when idling, the average small car engine can still be turning over at up to 1000rpm, and will comfortably hit at least three thousand plus at higher speeds – or 50 revolutions per second upwards.

Racing engines take this to another level entirely, with F1 engines peaking at 19,000 rpm in 2008 before being limited to a maximum of 15,000 from 2014 onwards. This is still a staggering 250 revolutions per second and the engine would be literally rubbing itself to pieces if not for the thin coating of oil keeping it going.

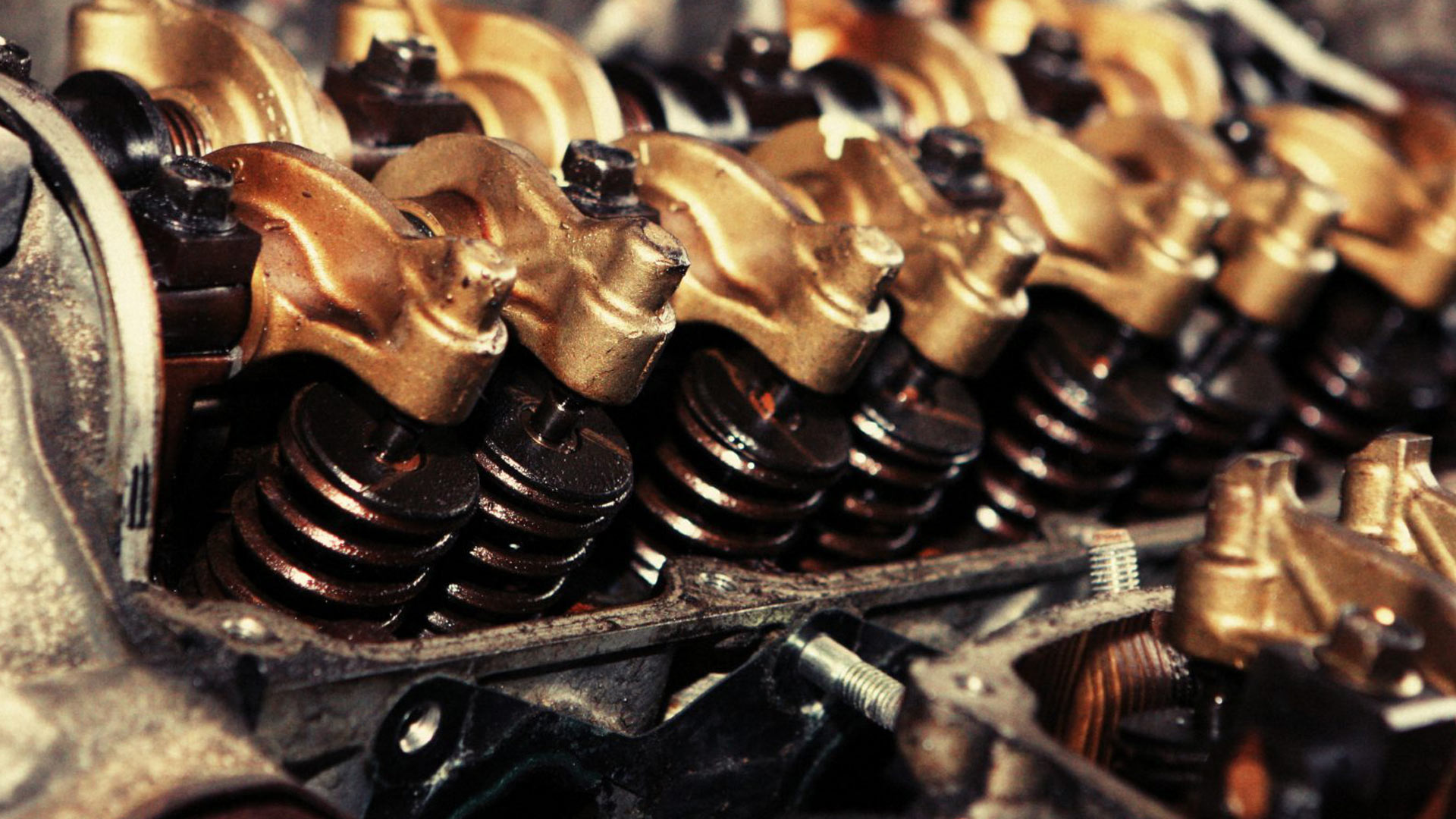

Without this coating, the metal components quickly heat up through the increased friction and begin shedding tiny particles and fragments as they become damaged. These fragments themselves will then cause even further degradation as they scratch and scrape between the precisely machined moving parts.

Eventually a part within an engine will degrade to the point of failure and break, killing the engine - it just depends on how soon this happens.

The better care the engine has received the longer it will last, but all engines will stop working at some point - explosively in some instances depending on which part has failed.

One of the most common parts to fail in these circumstances are the rod bearings which often leads to the connecting rod being fired out through oil pan - with only the still attached piston itself preventing it from going any further.

MIND THE GAP

The primary area of advancement in motor oil technology has revolved around covering the lubrication gap – that period of time from the moment of ignition to when the oil pump has fully circulated the oil throughout the engine.

That short time it takes to adequately coat all the moving parts can result in hundreds if not thousands of contacts between unprotected components.

It is thought approximately 65% of all engine wear happens during this gap and is why it’s still recommended you should wait a few moments after ignition before setting off.

Modern oils and lubricants do a much better job than their predecessors of clinging to components even when cold, and circulating through the engine faster. They also act as a cleaning fluid to wash away metal fragments and combustion residue quickly, and as a protection against corrosion.

However, even with the current level of technology it is impossible to completely eliminate engine wear within a combustion engine.

“SCHIENSH”

How oil actually prevents wear is quite incredible when you consider the stresses placed on an engine. Despite all the heat, pressure and abrasion of internal combustion, if oil is present and flowing adequately the parts never actually come into contact with each other - the oil forms a barrier between them.

How it achieves this is through a phenomena called a hydrodynamic wedge.

The rotation, or linear motion, of the moving part drags oil into the space between it and the stationary component and compresses it, forming a thicker layer ahead of the pressure point – the wedge. The viscosity of the oil prevents it from escaping and the pressure it’s then placed under acts to keep the two parts separate from each other, preventing friction.

When combined with modern bonding technology that enables oil to actually bond with metal surfaces on a molecular level so as to be near ever present, engine wear through part on part friction can be reduce to near zero – with the afore mentioned lubrication gap and combustion residues being the primary sources of damage.

KEEP IT CLEAN

Because of just how critical oil is to the health of your engine, it’s an area where a little effort goes a long way.

By using good quality oil and replacing it often, it will prolong the performance of your vehicle, reduce wear, and improve efficiency.