Fuel Injection Systems - Then & Now

The internal combustion engine has been around for over 150 years and in that time the fundamentals have largely remained the same, but the execution has matured into a beautifully elegant system.

In order for a combustion engine to do its job, it needs a way of getting fuel to…combust. However, as we’re sure many of you are aware; this isn’t quite as simple as it sounds.

There needs to be just the right mixture of fuel to air in order to perform properly. Engines used to be incredibly inefficient and ineffective. They created power. That’s about it.

Automobiles have become so integral to our way of life that we rely on them utterly. So much so there are strict regulations to keep their operation as clean and as efficient as possible

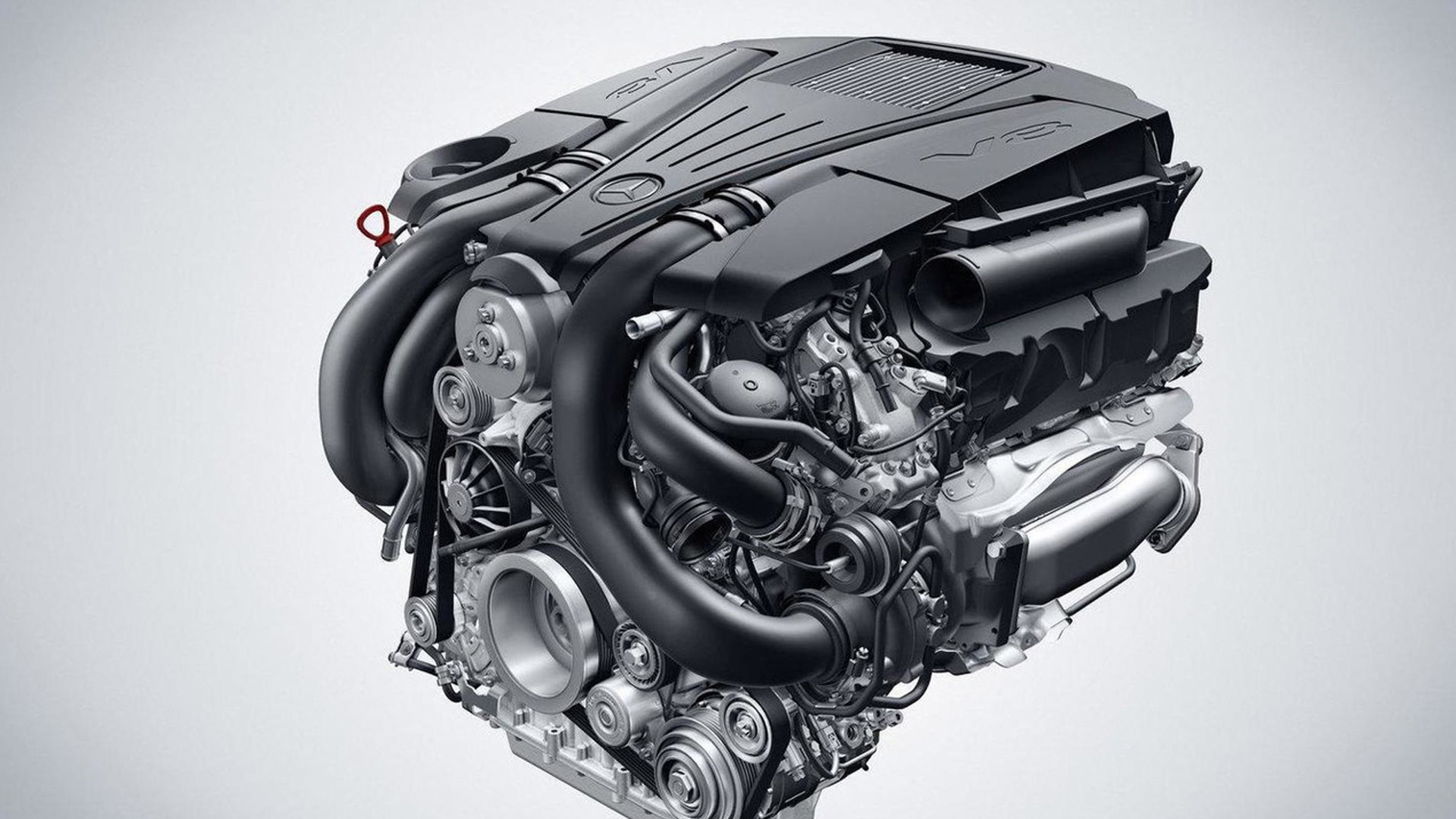

Meet the fuel injection system.

What ever happened to the carburettor?

The fuel injection system is one of those inventions that beg the question – why wasn’t this invented sooner?

A modern fuel injection system works by atomising the fuel at high pressure, mixing it with clean air as it passes the inlet manifold, before entering the combustion chamber of each cylinder.

The key element of the electronic modern fuel injection system is the word “electronic.”

These modern systems use a computer, oxygen sensor, injectors, fuel pump and pressure regulators to ensure the accurate mixture and delivery of fuel to the combustion chamber.

Too much fuel? The computer corrects the length of time the injector is held open.

Old-school carburettors couldn’t do this. If the mix was out – it was out. This often led to high emissions, poor fuel economy, misfiring engines, burnt valves and shorter engine life. Now you know why your lawnmower breaks down every spring.

If the fuel to air ratio isn’t correct in an injection system the computer fixes it. What if it can’t be corrected? The check engine light goes on.

Fuel injection systems provide lower fuel consumption, more power, increased reliability and massive future opportunity over the carburettor.

So, fuel injection systems are perfect?

Almost.

The amount of control that fuel injection systems provide over a traditional carburettor is unquestionable. What sends shivers down the spines of most mechanics is the thought of a fuel injection system breaking.

A carburettor is a beautiful piece of engineering. You can liken it to that of a clock mechanism or a high-calibre rifle. A system of mechanical components working in harmony.

If it stops working it’s a case of taking it apart, cleaning out the gunge and fixing. Now the idea of this probably sends shivers down the spines of many of you too, but at least you can physically see the problem. Even if you can’t fix it, you can identify there is a problem and then find someone who can.

Imagine that your laptop was built entirely from mechanical parts – something along the lines of the Difference Engine. If it crashed – you could open it up and see the part that’s jammed. If you were to open up your own laptop now, it would probably look the same inside, regardless of whether it was functioning or not.

If a fuel injection system stopped working – you’d be lucky to spot any physical signs of breakage. The easiest solution would be to replace the unit and hope that fixes the issue.

This is often expensive. Then again, how much money have you saved in fuel over the years?

Technology is only going to get better. Our requirements are becoming more specific and our expectations much higher.

The 4 year MOT exemption on new cars being a perfect example.

We simply don’t expect new cars to break down anymore. What seems to be a common trend with technology today is that it’s becoming more and more ‘throw-away.’

Once upon a time, everyone knew how to fix things. Children were brought up knowing how to change a spark plug.

That’s no longer the case.

As technology becomes more and more sophisticated – so do our expectations. Prices might be high but so is reliability. Technology is becoming more modular. If something breaks – just replace it.

The days of ‘tinkering’ may be over.