What's A Dual Clutch Transmission and How Does It Work?

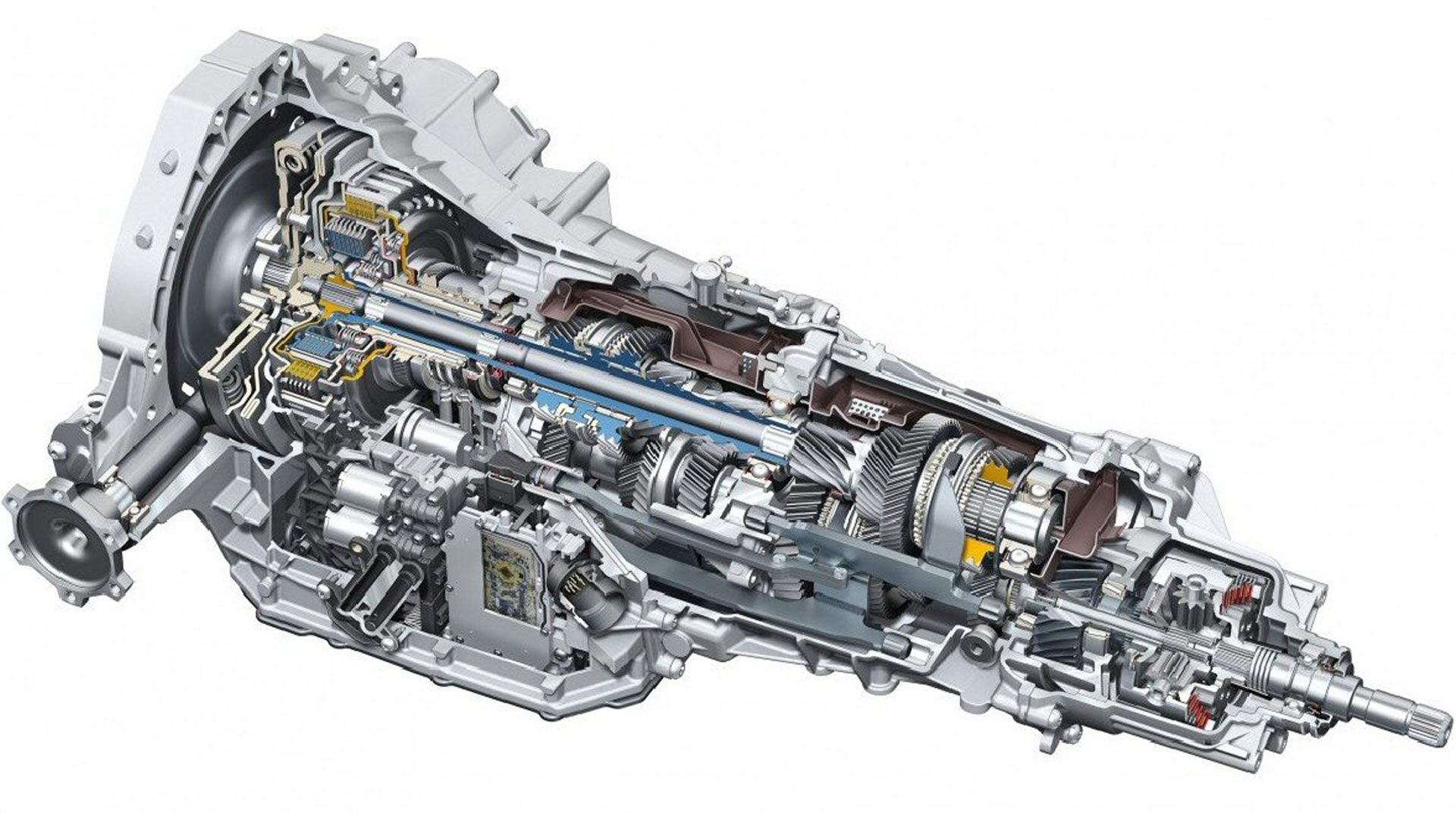

Despite what is undoubtably very clever and complex engineering, the Double (or Dual) Clutch Transmission (DCT), has a mixed reputation with drivers and has not achieved the level of ubiquity many thought it would.

Sitting in the middle ground between an automatic and a manual transmission, the simplest way of describing their operation, is that they’re an automatically operated manual transmission – achieved by using two clutches.

Doing away with the torque converter of a normal automatic transmission, they utilise the traditional gearing methods of a manual - but then split that gearing across two output shafts to allow power flow to shift between them incredibly quickly.

ORIGINS

Also referred to as a Direct Shift Gearbox (DSG), most car manufacturers have their own version or versions, but use them selectively across their ranges of vehicles – with the Volkswagen group the most invested in their implementation.

Like so many ‘new’ developments for automobiles, the double clutch transmission is an idea that had been around for a significant amount of time before finally being put to use, having been experimented with pre-World War two.

Its realisation had to wait until the 80’s, and it was Porsche who eventually became the first major adopter having worked on their own version since the 60’s.

The Porsche 956 released in 1983 received the distinction of being the first to feature one, and their complexity and expense kept them in the realm of motor racing and high-end super cars for the most part.

Space was also a considerable restriction. The electronics needed for the computerised control module had not yet reached the miniaturisation levels of modern times and so were quite sizeable and took up valuable engine bay space.

It wasn’t until 2003 that a production road car featured a DCT, in Volkswagen’s Mk4 Golf R32.

ADVANTAGES

The purpose behind a DCT is to reduce the gap between gear shifts to a minimum, with the benefits being improved performance and fuel efficiency.

The less time spent off the power changing gear during acceleration the faster the vehicle can accelerate - and by reducing the time spent off the power during gear changes in general, the better fuel economy will be as engine power isn’t wasted.

Gear changes on DCTs can now be measured in the milliseconds, faster than any driver is capable of, and still retain the advantages a manual gearbox has over an automatic.

How it achieves these lightning fast changes is by anticipating what the next gear needed will be, based on factors such as rate of acceleration or deceleration, current speed of travel and engine speed.

This allows the computer to have the predicted gear already engaged before the change is made.

OPERATION

Unless you’re already familiar with how a DCT works, you’re probably already questioning how this type of transmission can have two different gears selected simultaneously without exploding into a shower of shrapnel.

The clue is in the name but that’s only describing part of the process. Yes, there are two clutches, but simply having an extra clutch doesn’t really explain how a transmission can select more than one gear at a time.

The twin clutches are arranged concentrically – meaning one sits within the circumference of the other, crucially enabling them to both work on the same input shaft.

However, the input shaft connected to both the clutches is not one shaft, but two - with one of them sitting within the other and allowing each clutch to contact and act upon a different one.

The gears are split across the split input shaft by odds and evens, allowing the transmission to switch back and forth between them as the car accelerates and decelerates – pre-selecting each gear on the opposite input shaft to the one engaged.

The gears themselves are no longer engaged purely mechanically by the gear level either and are instead actuated by shift forks powered by pistons, engaging and disengaging as necessary.

When you shift gears, the gear level is signalling for these pistons to actuate and engage the synchronisers onto the chosen gear, and not mechanically engaging them itself.

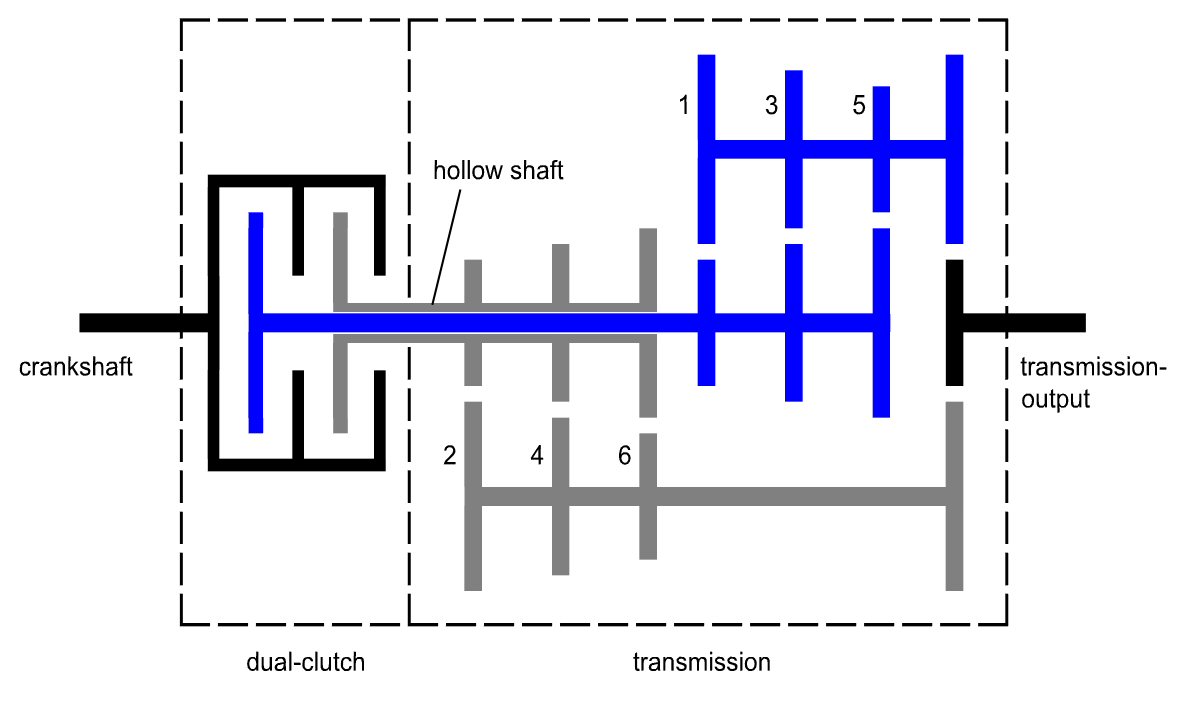

In this simplified diagram you can see how the input shaft is divided in two via a hollow shaft, with one running through the other and both controlled by the double clutch switching between them.

In this simplified diagram you can see how the input shaft is divided in two via a hollow shaft, with one running through the other and both controlled by the double clutch switching between them.

The gears work as a normal synchromesh transmission would, by utilising synchronisers to connect the gears to the output shafts.

Tracing a line from the blue clutch on the left, along the input shaft, up onto first gear on the first output shaft, and then continuing along and down onto the transmission output gives you first gear.

While this is happening, the computer is deciding which gear you’ll be wanting next. If you are accelerating it will almost certainly opt for second gear and connect this gear on other half of the input shaft so that it is ready as soon as you want to shift up into second.

On shifting, the clutches switch over and power transfers to the grey section of the input shaft, tracing a line along and down onto second gear and out onto the transmission output as before.

There’s a slight overlap between the two as the clutches engage and disengage, but the change is incredibly fast with almost no gap between the two speeds, giving the impression of a near seamless gear change.

It’s a very sophisticated system - but not one without its problems or detractors.

PROBLEMS

The system does run into problems when going from stationary to very slow speeds, where there’s a delay in engaging first gear but the driver is still depressing the accelerator waiting for power delivery. Once the system catches up and the gear is engaged, the car will then accelerate according to how fast the engine speed is - and if the driver has given it too much power it can cause the car to shoot forwards unexpectedly.

This problem can be largely attributed to unfamiliarity with the system, but other complaints are more directly related to its mechanical processes - although this is usually relevant for earlier model DCT/DSGs.

These include having to wait for the system to shift down gears when decelerating rapidly, as it is unable to skip gears due to the alternating method of operation between input shafts; and problems with reversing up hills where the system can get confused by which gear it should be engaging next.

Like any system, continued refinement and improvement eliminates problems and improves operation, and this could be the case here if given the development time. However, the writing could already be on the wall as some automotive manufacturers have already cast doubt over the future of the complex transmissions.

Advances made in automatic transmission technology have closed the gap to DCT/DSGs, and with automatics already selling in increasing numbers over manuals we could well see a time in the near future where manual transmissions phase out completely – leaving them to the enthusiasts.