Why We Use Iron In Car Components

It’s a common question amongst many consumers.

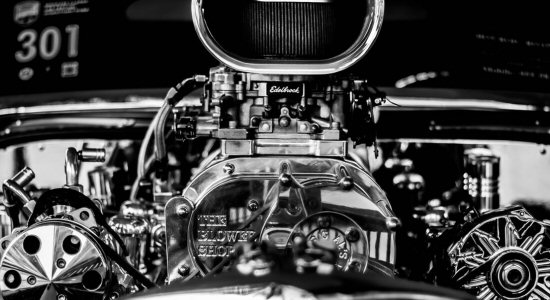

Why, considering all the innovation in materials and the ongoing concern with weight and fuel efficiency, are so many engine components still made from iron?

It’s not an unreasonable question either. Aluminium, steel, carbon fibre and magnesium are all used in cars and the developments in wonder materials like graphene means there are other options available.

The reasons are simple:

Iron is Reliable

Humanity has been using iron for centuries. We know how to find it, how to mine it and how to work it.

We know its mass and how much punishment it can take.

Basically we know how to get the best out of the metal. We’ve refined the casting process so the metal is at its absolute best before it becomes a steering knuckle, camshaft or one of dozens of other iron components.

It also has dimensional stability. This means it doesn’t distort under heat whereas other metals like aluminium do. Designers don’t have to make extra allowances for how the metal behaves during casting or under intense pressures.

Whilst it has its draw backs, iron is predictable when it comes to responding to stresses, impacts and the wear of daily and near constant use.

Iron is Strong

This may be something of an obvious fact but it’s relevant. Iron is incredibly tough which means it absorbs an awful lot of energy in the event of a collision.

It’s also very heavy.

Now for those with one eye on their Nurburgring times this may seem like a problem but weight in the right places is a good thing because it creates down force which gives you grip.

This is why super light sports cars often rely on large spoilers and diffusers (or the design of the car itself) to create down force. Because the car doesn’t generate enough on its own.

Iron is Versatile

Because of its ease of use and dimensional stability it can be worked into more or less any shape and then stay that way once you’ve finished.

It can be cast, stamped, beaten, drilled, welded, milled, machined, coated and painted.

Versatility means cast iron components (especially engine blocks and cylinder housings) are far easier to repair than if they were made from something else.

Whereas other materials cost more to produce and have greater limitations because how the metal responds to casting or lower melting points (aluminium brake rotors would be a disaster).

It’s not without its limitations of course but the benefits vastly out weigh them.

So if you’re every asked ‘why iron?’ the answer is simple: because it’s incredible.