EURAC's Insightful Experience at EuroBrake 2023, Barcelona

EuroBrake – the world’s largest annual brake technology conference – is a crucial event for the international braking technology community.

At this year’s meet, taking place between the 12th and 14th of September, participants and attendees from prominent sectors of the brake industry convened. Suppliers and manufacturers for both passenger cars and commercial vehicles were in attendance, including keen representatives from EURAC Poole.

This wasn't just any ordinary conference. It marked the first face-to-face congregation of industry magnates since the onset of the Covid-19 pandemic, with teams from across the globe gathered to discuss the path forward for the automotive braking industry.

The primary agenda revolved around the implications of the soon-to-be-implemented EURO 7 legislation.

This regulation, which addresses brake dust emissions, stands as a testament to the industry's commitment towards creating an environmentally sustainable future. As the world gradually awakens to pressing environmental issues, it's paramount for industries to re-evaluate and refine their practices, and the braking sector is no exception.

So, what does the EURO 7 entail for brake manufacturers?

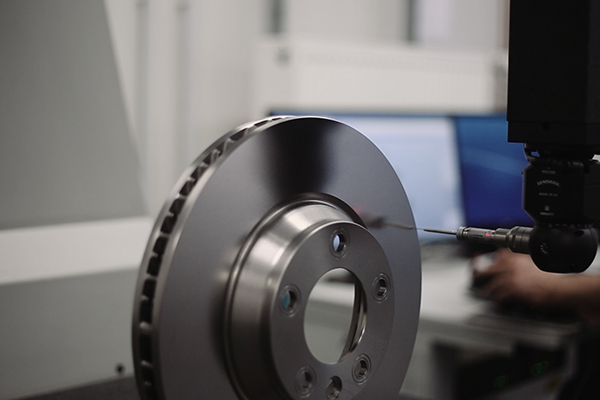

The law mandates strict limits on brake dust emissions. With rising global temperatures and increasing air pollution levels, the automotive sector is under the scanner - not just for tailpipe emissions, but also for non-exhaust emissions like brake dust. These dust particles, produced when the brake pads press against the rotors, have been identified as significant contributors to air pollution.

EURAC was at the forefront of these discussions. For us, attending EuroBrake wasn’t merely about compliance. It was a vital engagement to understand the market dynamics, collaborate with partners and realign our strategies to ensure a sustainable and competitive future.

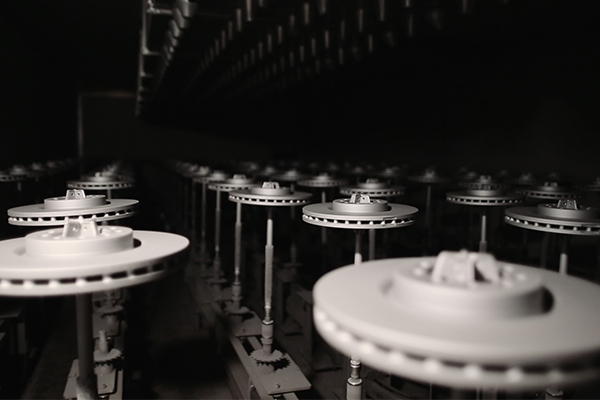

One of the most captivating revelations at EuroBrake was the introduction of dust particulate filter systems for brake rotors, spearheaded by Mann+Hummel.

This innovation aims to substantially reduce the particulate matter produced during braking, presenting a potential solution to meet the stringent EURO 7 standards.

Yet, the highlight that garnered significant attention was the unveiling of the laser cladding and grinding technique for brake rotors. By establishing an exceptionally hard surface layer on the rotors, this groundbreaking technology promises to curb dust emissions by an astonishing 95%. While the buzz was undeniable, there were also murmurs of the hefty investment required to harness this method. However, as with all budding technologies, it's essential to strike a balance between the initial costs and the long-term benefits, both environmental and financial.

Being at EuroBrake offered EURAC a chance to interact with vehicle manufacturers, OEMs and Tier 1 suppliers.

These invaluable discussions shed light on the collective vision for the industry. It became clear that while challenges are imminent with the EURO 7 legislation, the industry's stalwarts are determined to innovate and adapt.

For EURAC, this was more than a conference. It was an essential opportunity to keep our finger on the pulse of the automotive market. Engaging with both existing partners and potential collaborators, we could fine-tune our vision and align our development strategies with the broader industry trends. It's not just about technical feasibility; it's about maintaining a competitive edge in a rapidly evolving market.

EuroBrake 2023 was an enlightening experience for the EURAC Poole team. It underscored the industry's resilience, adaptability, and unwavering commitment to a greener future. As EURAC looks forward, we're energised and inspired, ready to tackle the challenges and seize the opportunities that lie ahead.